The Barrel Puzzle

Blog Post

August 2022

How does a winery prepare for harvest? Among the many tasks is preparing the cellar to receive new oak barrels. This 2022 vintage marks Ridge Vineyards’ 60th harvest; here, we describe the steps we took to prepare for harvest at our Monte Bello Winery:

Understanding the Challenges of our 1890s-era Winery Building

“Every year during the late spring and early summer months, our production team is busy moving empty barrels around in order to make room for the new barrels that will be arriving for the upcoming vintage. As I will explain, this is much easier said than done and can become a task of monumental proportions.

“To begin with, each of these empty barrels weighs around 100 pounds. Add to this the awkward shape and sharp metal edges and one quickly realizes how difficult they are to move. We have no shortage of back braces and steel-toed boots in the cellar.

“Most wineries will store their barrels on metal racks that hold two barrels each and can be moved using a forklift and are stacked on top of each other. Here at Monte Bello, we stack our barrels by hand on top of each other in a pyramid fashion. This helps to maximize space but is also our only option as it is too steep and tight for a forlklift to operate here.

“Because the winery is built on a steep slope, our production areas are at various elevations on the mountain. Moving equipment and barrels from the top cellar to the bottom cave and vice versa can be a Herculean task. However, we do have some helpful tools for this. We use a barrel hoist that will hold one barrel on a platform and can be raised up and down to the various heights of the stacks. This also comes in handy when we need to move barrels inside from one level to the next where only a spiral staircase exists. We will also use a good old fashion dolly to move the barrels around and to bring them outside of the cellar to be loaded onto a truck and driven to the next cellar up or down the property.”

From Daunting Task to Fun Challenge

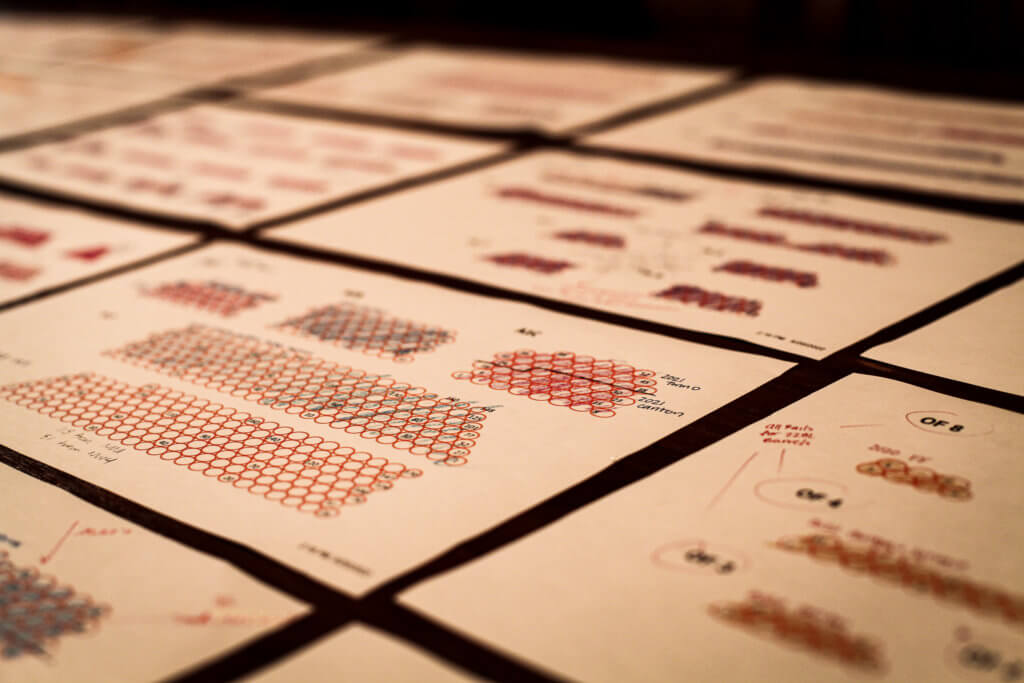

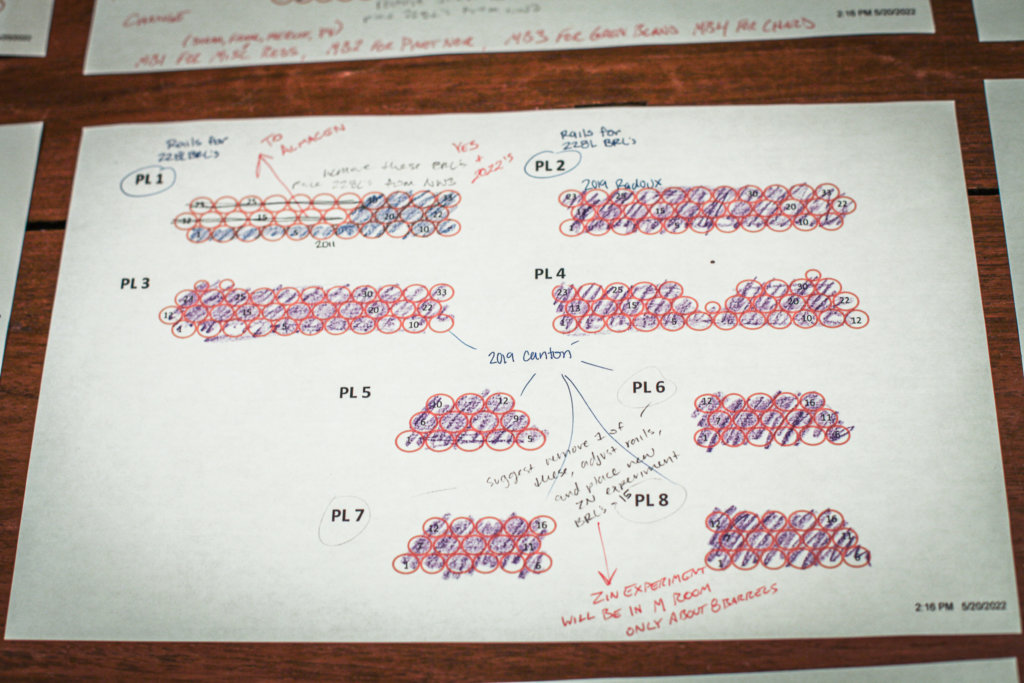

“The physical challenges of these barrel movements is just one part of the puzzle. The main challenge is in the logistics and planning involved. There are ten different barrel storage areas ranging in size from a large warehouse to small nooks and crannies inside our hand-dug limestone cellar. The hand-stacked barrels range from 2 high to 7 high pyramids. We use barrel maps to help us to decide where each barrel type will go and for which wines. For example, we will put the Chardonnay barrels in the bottom cave and the Monte Bello Cabernet barrels in the top cellar. We also try to put the older barrels in our tippy top building as this is the easiest place to move them out by truck when it is time to retire them from our program. We typically use our barrels for six to seven years.

“One thing that must be considered when planning where these barrels will be stacked is the age of the barrels. Some of our wines are aged in several different vintages of barrels so we need to be careful not to get them all mixed up within our stacks. This is tricky because we also do not want a single lot of wine to be in multiple locations. Another consideration is the type of barrels (American 200L vs. French 225L, Bordeaux shape vs. Burgundy shape). The different sizes of barrels do not stack well together so we try to keep as many of the same shape and size together. This can be difficult when we want a certain percentage of new oak and old oak and American oak and French oak in the same wine.

“Working together as a team, the winemaker, cellar master, and lab manager all contribute to the barrel plan for the year. As we had all of our barrel maps strewn across the table, we realized that the project seemed similar to solving a giant puzzle. Once we realized this, it became less daunting and more of a fun challenge.”

Related Links

Stay up-to-date with the latest RIDGE news, wine releases, and special offers – join our mailing list.

Wait!

In order to qualify for user related discounts, you must log in before proceeding with checkout. Click the button below to log in and receive these benefits, or close the window to continue.

Log In